Fakir Knitwears Limited is a comprehensive manufacturing and exporting company of Bangladesh. It comprises the ultra modern plants related to garment industry, such as independent knitting, dyeing, sewing, finishing and packaging with sufficiently supportive backward linkage facilities.

Nowadays, our products sell well all over the world, such as America, Europe & East Asia. Our company sticks to the policy of high quality, developing by credit standing, and gaining the world through honesty. We strongly believe in fair trade liabilities and practice in business towards our esteemed clients. Meanwhile we also carry out a strict quality management system in accordance with ISO 9001 requirements.

10,500

Employees

$123 Millions

Yearly Turnover

1,152,000 SQFT

Area Premises

1,029,362 SQFT

Production Floor

38 Years Of

Experience

Knitting Garments Industry

The core mission of FKL is to provide its customers the best value for their money by way of facilitating them with one-stop knitwear manufacturing as well as sourcing services whereby satisfaction is always guaranteed leaving virtually no room for any complaint. FKL pursues its mission complying with all of the requirements on humanitarian ground, ensuring excellent management practices, and reinforcing working environment in a way that it would be viewed as a model for others to appreciate and follow as “A BETTER WORKING PLACE”.

The vision of Fakir Knitwears Ltd. is to set a benchmark, not only in Bangladesh but also it would be recognized as one of the leading garment manufacturers on the global stage.

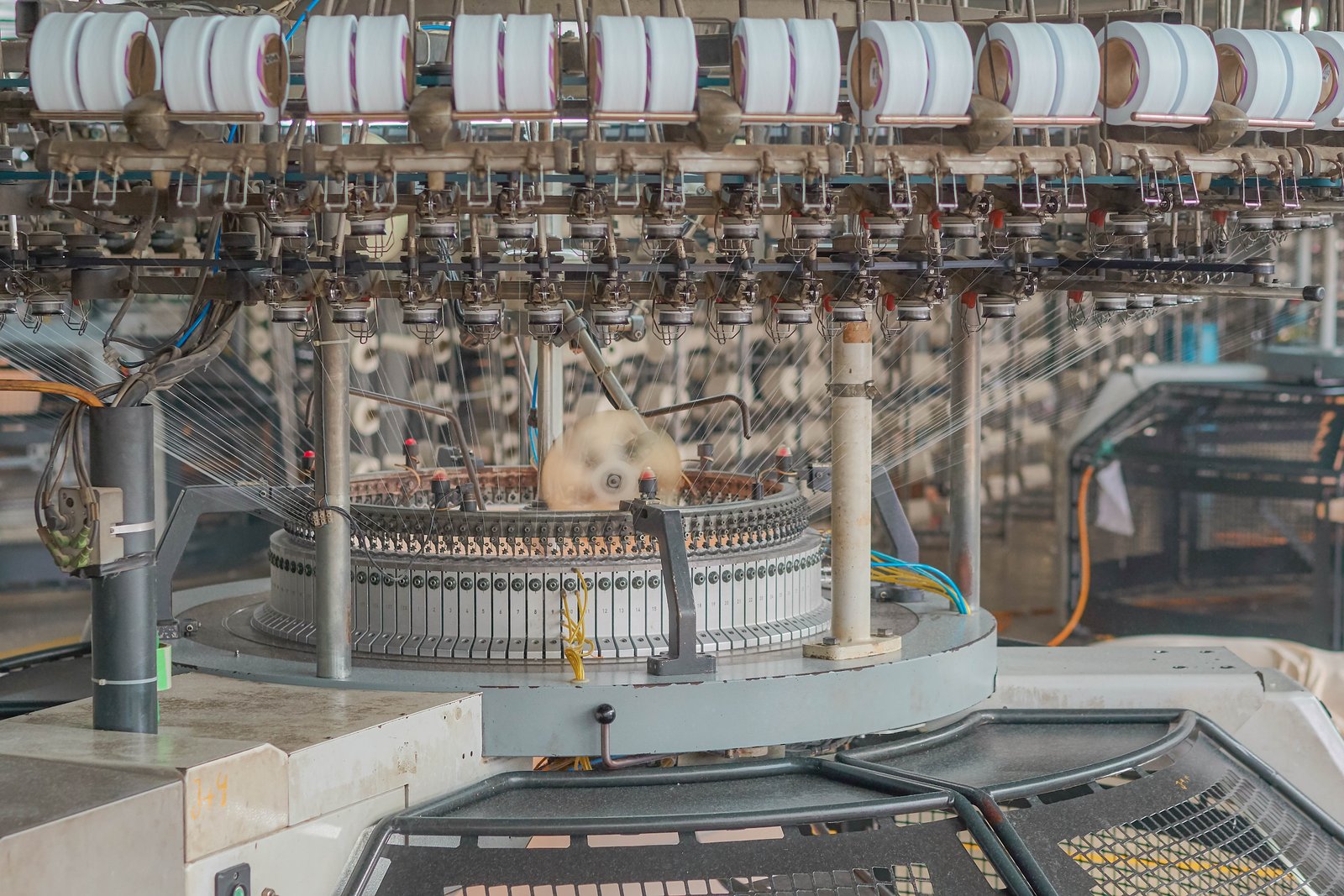

The knitting section is equipped with top of the-line machinery, Fukuhara of japan, mayer and cie of Germany, and jung-long of Taiwan. The machines are equipped with special attachments to produce Lycra fabrics. A well-integrated system of stringer quality measures checks all fabrics meticulously to eliminate contamination and other faults. We always believe that yarn is the core material for knitwear therefore we use best quality yarn from world renowned spinning mills.

Knitting Capacity: 55 Tons/Day

| Circular Knitting Machine | |||

|---|---|---|---|

| Single Jersey | Double Jersey | Auto Stripper | Jacquard |

| Type of Machines | Brand | Number of Machines |

|---|---|---|

| S/J Open Width | Masa, Jiunn Long, Mayer & Cie, Fukuhara | 48 |

| S/J Tube Dia | Masa, Jiunn Long, Mayer & Cie, Fukuhara, Quantex, King Knit | 49 |

| S/J Machanical Jacquard | Jiunn Long, Santec | 02 |

| 3th Fleece | Fukuhara | 02 |

| Rib / Interlock | Jiunn Long, Masa, Lein Yaun, Fukuhara | 35 |

| Engr. Stripe S/J | Fukuhara | 06 |

| Engr. Stripe Rib / Interlock | Fukuhara | 01 |

| Fabrics Inspection | UZ-900-31, Proknit | 11 |

| Rewinding Machine | SMEW-Filcono | 01 |

| Machines Name | Brand | Origin | Number of Machines |

|---|---|---|---|

| Flat Bed Knitting m/c | Stoll (Jacquard) | Germany | 10 |

| Gray Fabric Inspection m/c | Uzu cloth insp. m/c | Thiland | 05 pcs for open 05 pcs for tube |

The company’s ultra modern process house comprises the latest equipment and machinery in the world. Latest soft flow dyeing machines from SCLAVOS (Greece), FONGS (Hongkong), PMM (Turkey), ACME (Taiwan). Machines can dye polyester under high temperature and pressure conditions. Producing dyed fabric without any pilling due to low liquid pressure and double nozzle system, without putting ant stress on the fabric.

Dyeing Capacity: 50 Tons/Day

| Machine Name | Brand | Country | Number of Machines |

|---|---|---|---|

| Winch | Fongs | China | 15 |

| Winch | Sclvos | Greece | 02 |

| Winch | PMM | Turkey | 03 |

| Winch | Acme | Taiwan | 01 |

| Digital PH Meter | Hanna | – | 01 |

| Winch | Fongs | China | 15 |

| Winch | Sclvos | Greece | 21 |

| Winch | Fongs | China | 04 |

| Winch | Canler | Turkey | 01 |

CAD Section: First stage in the production line is the pattern making section. Our CAD division uses two software:

Cutting Section: The second stage in line is the cutting section. In this section, materials are cut in the pattern determined and designed in the previous section.

Cutting Capacity: 3,50,000 Pcs/Day.

Sewing Section: The next stage is the sewing section. It has two steps. The 1st step being the sewing part uses various types of sewing machinery, while in the 2nd step, uses button hole & button attaching machinery to complete the making operation. Dynamic Industrial Engineering team is continuously developing the different methods to get the maximum productivity and efficiency from the sewing lines. Our Sewing machines are equipped with auto trimmers, Lock stitch Button stitch, Chain stitch machines and Auto Button Hole Machines. We’ve well equipped training center which continuously producing the multi skill sewing operators which helps the production lines to face the challenges of any styles. All sewing lines are under constant and continuous inspection by quality monitoring team to generate the perfection. To ensure the in time delivery & capacity planning we’re using world renowned production planning software named ”FASTREACT”.

Sewing Capacity: 3,00,000 Pcs/Day.

Sewing Machines: 3050 NO'S.

Sewing Lines: 115.

Finishing Section: At this stage products goes through various stages like removal of loose thread, folding etc & hanged with hanger & poly bag. Garments finishing section is equipped with steam press with vacuum table. The other finishing machineries are needle detector, thread blowing, strain removing, carton box striping etc.

Printing unit is well equipped with necessary equipments including Auto Print Machine. We are capable to print various types including flock, discharge, emboss, and sugar print, all types of stone and studs heat transfer and many special types of printing.

Fakir Knitwears Ltd. Has sophisticated computerized embroidery unit with sequins, beading & roof embroidery. The embroidery unit is capable of 80 million stitches per day.

| Machine Name | Origin | Brand | Head | Number of Machines |

|---|---|---|---|---|

| Electric multi head automatic machine | Japan | Tajima | 20 | 20 |

| Applic laser cutter | China | Golden | n/a | 04 |

| Fusing Machine | Japan | Hashima | n/a | 02 |

We have included best efficient garment washing plant that has a capacity of 45000 pcs garment (Normal Wash) & Pigment washing 25,000 pcs garments per day.

Fakir Knitwears Limited manufactures and export knitwear garments for men’s, ladies, children, boys, girls, infant etc. We also produce sportswear, maternity wears as well. Our state of the art knitwear covers almost all of the fibers available in the market. Our specific products include: T-Shirt, Tank Top, Leggings, Pyjama Set, Polo Shirt, Boxer Shorts, Night Wears, Accessories etc. Our Upcoming projects are Woven and Lingerie products.

Environment and its pollution are a prime issue of concern for all. We work tirelessly to ensure that our environmental impact is reduced, our work processes are more efficient and effective work processes and that we engage in socially responsible initiatives. Fakir Knitwears Ltd. has set up a modern ETP plant for proper treatment of industrial waste before it is released into the environment. Our another green expansion is green building, Solar Power system and Rainwater Harvesting.

17%

ENERGY SAVINGS

13%

CARBON FOOTPRINTS

37%

RAIN WATER WITH HARVESTING

100%

ZDHC MRSL COMPLIANCE

We FKL have set a greenhouse gas emissions target covering our scope 1 & 2 emissions in line with the latest criteria and recommendations of the SBTi which supports the ambition of the Paris Agreement in limiting global temperature rise to 1.5 degrees Celsius above pre-industrial levels.

FKL commits to reduce absolute scope 1 & 2 GHG emission 42% by 2030 from base year 2023.

We FKL have been working with one of our customers (global brand) to understand and address our Scope 3 emissions.

We confirm that the Tier 1 and Tier 2 manufacturing sites we contract with have set greenhouse gas emissions reduction targets covering the manufacturing sites’ Scope 1 & 2 emissions, in line with criteria and recommendations of the SBTi.

Supplier Coal Phase Out Public Statement

We Fakir knitwears Ltd. have been working with one of our customers (global brand) to understand and address our carbon emissions.

We Fakir knitwears Ltd. commit to phasing out/moving away from [delete as appropriate] coal for owned and contracted Tier 1 and Tier 2 manufacturing sites used for their product as soon as possible, and latest by 2030.

Supplier Scope 3 Public Statement

We Fakir knitwears Ltd. have been working with one of our customers (global brand) to understand and address our Scope 3 emissions.

We Fakir knitwears Ltd have measured our Scope 3 Category 1 and Category 4 emissions covering their product and have set a greenhouse gas emissions reduction target covering coving those emissions in line with version 1.2 of the SBTi Net Zero Standard, which supports the ambition of the Paris Agreement in limiting global temperature rise to 1.5 degrees Celsius above pre-industrial levels.

FKL commits to reduce Scope 3 Category 1 and Category 4 GHG emission 42% by 2030 from base year 2024.

We are proud enough that we have got several friends who are renowned with their own identity around the world. We are consistently looking for new friends to extend our existences over the global market of knitwears. We believe that who makes friendship once with us become partner forever.

Buyers

Kayempur, Fatullah, Narayanganj-1420.

Phone: +8809613444555

Fax:

Email: fklinfo@fakirgroup.com.

© All right reserved by Fakir Knitwears Ltd.